Develop PLC Programming Examples on Industrial Automation according to the logic given below,

- A Saw, Fan and oil pump all go ON when a start button is pressed.

- If the saw has operated less than 20s, the oil pump should go off when the saw is turned off and the fan is to run for an additional 5s after the shutdown of the saw.

- If the saw has operated for more than 20s, the fan should remain on until reset by a separate fan reset button and the oil pump should remain on for an additional 10 s after the saw is turned off.

- Write a program that will implement this process.

PLC Programming Examples

Program Description:

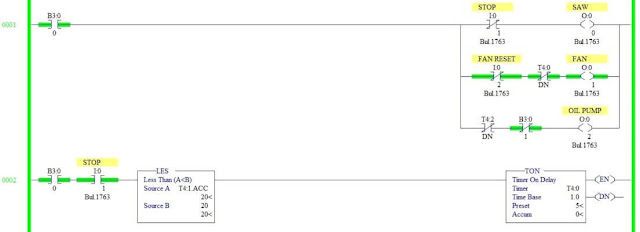

Rung 0000:

Start/Emergency Stop PB latched with memory B3:0/0.

Rung 0001:

B3:0/0 enabled to turn on Saw (O: 0/0), Fan (O: 0/1 ) and Oil pump (O:0/2).

Normally closed contact of Stop switch is in series Saw output to turn off.

Fan reset switch and Timer T4:0 is connected to turn off Fan when condition meets.

Timer T4:2 done a bit and memory bit is to turn off the oil pump.

Rung 0002:

When the stop is pressed, according to the logic mentioned in point 2, Fan output (O: 0/2) needs to turn off after 5s.

Comparator block restricts the timer T4:0 to run after the 20s of Saw operation.

Rung 0003:

Timer T4:1 runs when the start is pressed. When the stop is pressed at any point after the 20s, Saw output will go off.

After 10s, the oil pump will go off. This operation is done by Timer T4:2. Timer T4:0 done bit is used to restrict the Timer T4:1 operation when T4:0 is ON.

Rung 0004:

Less than a comparator block is used to perform the logic mentioned in point 2, to turn off Fan when saw output operation was less than 20s.

Program Output:

Now we see the simulation of above ladder logic for different conditions as mentioned below.

When Start PB is pressed

When Stop switch pressed before the 20sWhen Stop switch pressed after the 20s

When Fan reset switch is pressedConclusion:

We can use this example to understand the programming logic in Allen Bradley PLC.

-END-

Comments

Post a Comment