This article is about to add an unspecified CPU in Siemens TIA portal.

Unspecified CPU in Tia Portal

During software setup, you get to know that CPU which installed in hardware doesn’t contain a part number and you also don’t have anything else related to its which can give us a part number.

In such a case, siemens provide an option to detect unspecified CPU. Do follow the below steps to know the process of adding such CPU.

Step 1:

Open TIA PORTAL. Create a new project or open an existing one.

Step 2:

Do follow the steps as shown in the below window.

In Simatic option, you Can expand any option to add CPU which you want to add.

Step 3:

Here. I will add the CPU using the Simatic-1500 option.

Expand CPU and choose unspecified CPU as shown in the below window.

Click “Add” to proceed.

Step 4:

The following window will open up. You can see unspecified CPU is added.

Step 5:

Click on “Detect” as shown in the below window.

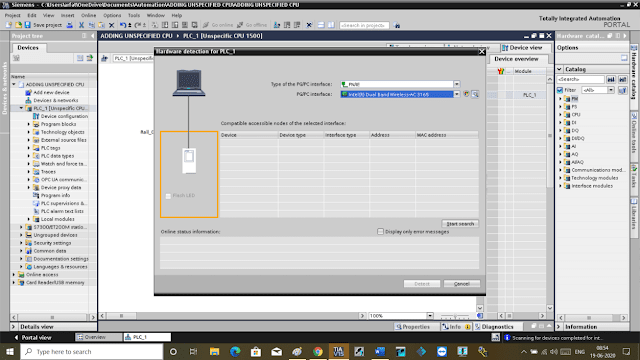

Step 6:

The following window will open.

Step 7:

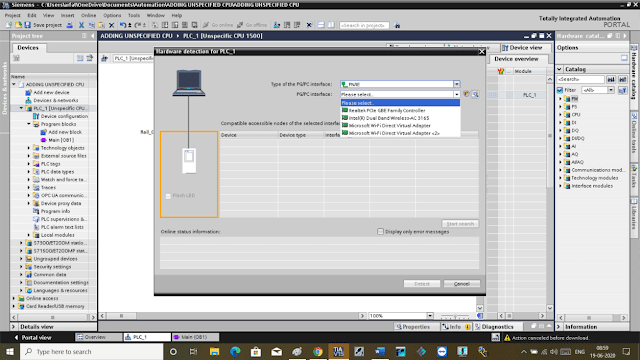

As you can see in the below window when I drop down the list it won’t contain a simulator option.

But simply you have to choose the method of communication you are using and hit the “start search” button. Where you can find a CPU and click on “detect” to add CPU.

As I don’t have actual PLC, I can’t show you detect procedure but you can find it by following the last step (online).

END

Comments

Post a Comment