Transmitter Suppression and Elevation

A very common scenario for liquid level measurement is where the pressure-sensing instrument is not located/installed at the same level as the 0% measurement point. The following photograph shows an example of this, where a differential pressure transmitter is being used to sense hydrostatic pressure of water inside a tank:

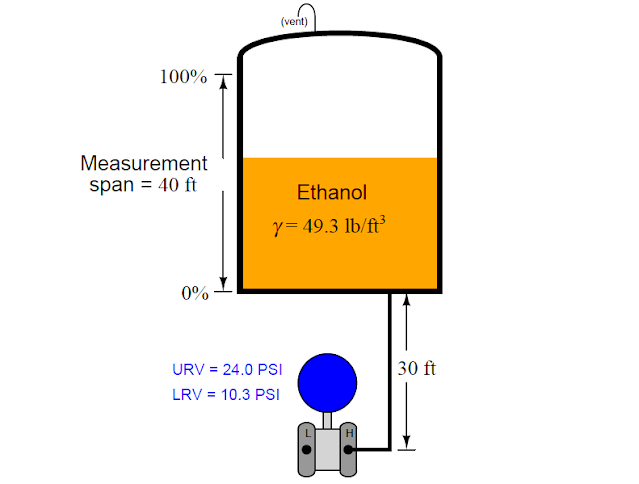

Consider the below example of a pressure sensor measuring the level of liquid ethanol in a storage tank. The measurement range for liquid height in this ethanol storage tank is 0 to 40 feet, but the transmitter is located 30 feet below the tank:

Note : A Vent is connected at the Top of the tank, so if any gas or pressure exists above the liquid in the tank will be vented out.

This means the transmitter’s impulse line contains a 30-foot elevation head of ethanol, so the transmitter “sees” 30 feet of ethanol when the tank is empty and 70 feet of ethanol when the tank is full. When there is no ethanol in the tank, pressure transmitter senses 10.3 psi (assumed) because it installed the tapping point and this causes extra pressure on the transmitter. as A 3-point calibration table for this instrument would look like this, assuming a 4 to 20 mA DC output signal range:

Another common scenario is where the transmitter is mounted at or near the vessel’s bottom, but the desired level measurement range does not extend to the vessel bottom:

In this example, the transmitter is mounted exactly at the same level as the vessel bottom, but the level measurement range begins at 4 feet up from the vessel bottom. At the level of castor oil deemed 0%, the transmitter “sees” a hydrostatic pressure of 1.68 PSI (46.5 inches of water column) and at the 100% castor oil level the transmitter “sees” a pressure of 3.78 PSI (105 inches water column). Thus, these two pressure values would define the transmitter’s lower and upper range values (LRV and URV), respectively.

The term for describing either of the previous scenarios, where the lower range value (LRV) of the transmitter’s calibration is a positive number, is called zero suppression. If the zero offset is reversed (e.g. the transmitter mounted at a location higher than the 0% process level), it is referred to as zero elevation.

If the transmitter is elevated above the process connection point, it will most likely “see” a negative pressure (vacuum) with an empty vessel owing to the pull of liquid in the line leading down from the instrument to the vessel. It is vitally important in elevated transmitter installations to use a remote seal rather than an open impulse line, so liquid cannot dribble out of this line and into the vessel:

Note : As you are about to see, the calibration of an elevated transmitter depends on us knowing how much hydrostatic pressure (or vacuum, in this case) is generated within the tube connecting the transmitter to the process vessel. If liquid were to ever escape from this tube, the hydrostatic pressure would be unpredictable, and so would be the accuracy of our transmitter as a level-measuring instrument. A remote seal diaphragm guarantees no fill fluid will be lost if and when the process vessel goes empty.

In this example, we see a remote seal system with a fill fluid having a density of 58.3 lb/ft3, and a process level measurement range of 0 to 11 feet of sea water (density = 64 lb/ft3). The transmitter elevation is 6 feet, which means it will “see” a vacuum of −2.43 PSI (−67.2 inches of water column) when the vessel is completely empty. This, of course, will be the transmitter’s calibrated lower range value (LRV). The upper range value (URV) will be the pressure “seen” with 11 feet of sea water in the vessel. This much sea water will contribute an additional 4.89 PSI of hydrostatic pressure at the level of the remote seal diaphragm, causing the transmitter to experience a pressure of +2.46 PSI.

Note : The sea water’s positive pressure at the remote seal diaphragm adds to the negative pressure already generated by the downward length of the capillary tube’s fill fluid (−2.43 PSI), which explains why the transmitter only “sees” 2.46 PSI of pressure at the 100% full mark.

Comments

Post a Comment