Measurement principle

Continuous non‐contacting ultrasonic level measurement is based on the time of flight principle.

An ultrasonic level instrument measures the time between sound energy transmitter from the sensor, to the surface of the measured material and the echo returning to the sensor.

As the speed of sound is known through the travel medium at a measured temperature, the distance to the surface is calculated. Level can be calculated from this distance measurement.

Echo Processing built in to the instrument can allow the instrument to determine the material level of liquids, solids or slurries even in narrow, obstructed or agitated vessels.

Limitations

Ultrasonic is seldom used in upstream hydrocarbon process stream for level measurement; it might be used in atmospheric utilities applications. In applications which are susceptible to vapour density variation, compensation reference pin should be used.

Maximum measurement distance should be checked against the technology (above 30 m the reflectivity may be reduced and might cause a measurement error/problem).

Ultrasonic sensors have, as physical limitation, a blocking distance (close to the sensor) where they cannot measure reliably, e.g. 0.25 metres.

Vessel pressure limitation should approximately be, e.g. 0.5 bar or less. Higher pressure may introduce uncertainty in the level measurement.

Vapour, vacuum or temperature gradients can influence the speed of sound and consequently can cause incorrect measurements.

Presence of foam or heavy turbulence on the surface of the measured material can cause unreliable measurement.

Selection

As ultrasonic is non‐contacting, even abrasive or aggressive materials can be measured. Vessel height and head room should be considered to select an instrument with suitable minimum and maximum range.

Design

Ultrasonic sensors should be made of a material suitable for the measured medium (e.g. PVDF or ETFE) Solid construction and a self‐cleaning action on the face of the sensor provide a reliable, low maintenance product.

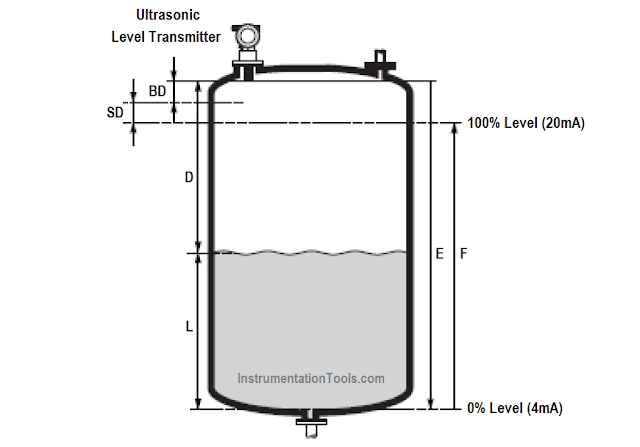

- BD : Blocking Distance

- SD : Safety Distance

- E : Empty Calibration ( Zero Point )

- F : Full Calibration ( Span )

- D : Nozzle Diameter

- L : Level

Comments

Post a Comment