A displacer level transmitter consists of a displacer element which is suspended from a hanger with a torque tube which is connected to the transmitter head.

The displacer element is designed to be heavier than the liquid in which it is being used so that, even when fully immersed in the liquid, so it still exerts a downward force on the hanger.

Displacer Level Transmitter Dry Calibration

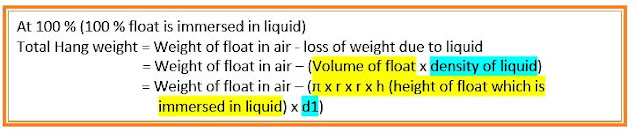

As the liquid in the vessel rises to cover the element, a buoyancy force is created which is equal to the weight of the liquid displaced by the element (Archimedes’s principle). This is seen by the transmitter as an effective reduction of the hanging weight of the element, and, as the displacer element hanging weight is proportional to the liquid level around it, the electronics in the transmitter head can give readout of liquid level.

The Archimedes Principle:

Archimedes principle states that the buoyant force exerted on a body immersed in a fluid is equal to the weight of the fluid the body displaces

Advantages

Displacer transmitters are widely used. Able to operate at extremes of pressure and temperature, and commonly used to measure interface level measurement.

Limitations

The accuracy of the level measurement is dependent upon correct calibration of the instrument at operating conditions. If these conditions would change (Density), the level reading will be incorrect. Torque tube displacer transmitters in particular require regular maintenance and calibration checks, and can suffer from damage during surge conditions.

Dry Calibration of level transmitter:

Dry Calibration with Weights for liquid level :

Suppose level transmitters which float weight is 3.0 kg and float length and diameter is 40 cm and 8 cm. Calculate the weight for dry calibration.

Density of water: 1 gm/cm3

Length of float (L): 40 cm

Diameter of float (D): 8 cm

Density of water (d): 1 gm/cm3

Weight of float: 3.0 kg = 3000 gm

So, r = 8/2 cm = 4 cm

So, Total Weight at 0% = 3000 gm = 4 ma

So, Total Weight at 25% =

= 3000 – (3.14 x 4 x 4 x10 x 1)

= 300 – 502.4

= 2497.6 gm = 8 ma

So, Total Weight at 50% = 3000 – (3.14 x 4 x 4 x20 x 1) = 300 – 1004.8 = 1995.2 gm = 12 ma

So, Total Weight at 75% =

= 3000 – (3.14 x 4 x 4 x30 x 1)

= 300 – 1507.2

= 1492.8 gm = 16 ma

So, Total Weight at 100% =

= 3000 – (3.14 x 4 x 4 x 40 x 1)

= 3000 – (2009.6 x 1)

= 990.4 gm = 20 ma

The 4ma and 20mA equivalents of weights are used to configure the displacer level transmitter

Interface level is measured with dry weight calibration

Suppose level transmitters which float weight is 3.0 kg and float length and diameter is 40 cm and 8 cm. Calculate the weight for dry calibration. Where two process fluids is present

Density of higher fluid (d1)(Liquid): 0.8 gm/cm3

Density of lighter fluid (d2)(Gas) : 0.15 gm/cm3

Length of float (L): 40 cm

Diameter of float (D): 8 cm

Density of water (d): 1 gm/cm3

Weight of float: 3.0 kg = 3000 gm

So, r = 8/2 cm = 4 cm

So, Total Float immersed at 0% =

= 3000 – (3.14 x 4 x 4 x40 x 0.15)

= 3000 – 301.44

= 2698.56 gm = 4 ma

So, Total Float immersed at 25% =

= 3000 – (3.14 x 4 x 4 x 10 x 0.80) – (3.14 x 4 x4 x 30 x 0.15)

= 3000 – (401.92) – (226.08)

= 2372 gm = 8 ma

So, Total Float immersed at 50 % =

= 3000 – (3.14 x 4 x 4 x 20 x 0.80) – (3.14 x 4 x4 x 20 x 0.15)

= 3000 – (803.84) – (150.72)

= 2045.44 gm = 12 ma

So, Total Float immersed at 75% =

= 3000 – (3.14 x 4 x 4 x 30 x 0.80) – (3.14 x 4 x4 x 10 x 0.15)

= 3000 – (1205.76) – (75.36)

= 1718.88 gm = 16 ma

So, Total Float immersed at 100 % =

= 3000 – (3.14 x 4 x 4 x 40 x 0.80)

= 3000 – (1607.68)

= 1392.32 gm = 20 ma

The 4ma and 20mA equivalents of weights are used to configure the displacer level transmitter

Article by :

Ashish Agrawal

Comments

Post a Comment