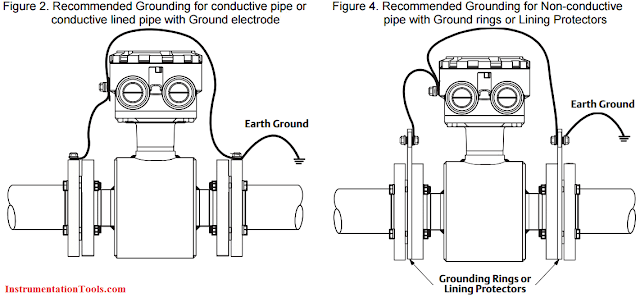

Proper installation and grounding of magnetic flowmeters is important for accurate, reliable measurement performance. Stray AC or DC currents through the fluid or instrument can produce noise signals that may in turn interfere with the relatively low flow signals generated in today’s modern pulsed DC magmeter. Manufacturers provide a variety of elements (ground straps, ground electrode, ground rings, lining protectors) and directions for the standard grounding of the magmeter.

Some Process conditions exist in which the user cannot or should not make use of the traditional grounding connection to adjacent piping and to earth ground. These flow measurement applications are frequently encountered in electrolytic processes and cathodic protection applications.

In this case, the fluid passing through the magmeter sensor may be at a potential significantly higher or lower than earth ground, and a connection to earth ground may be detrimental to the performance and even the reliability of the magmeter.

These applications are typically compounded by the use of non-conductive or lined pipe and may feature acid or caustic flows which may necessitate the use of expensive wetted electrodes and grounding materials such as titanium, platinum, or tantalum. Please refer to section titled “Special Applications” for complete details regarding these special installation requirements

Magmeter Operating Principle

The operating principle of the magnetic flow meter is based on Faraday’s law of electromagnetic induction, which states that a voltage will be induced in a conductor moving through a magnetic field.

Faraday’s Law: E = kBDV

The magnitude of the induced voltage E is directly proportional to the velocity of the conductor V, conductor width D, and the strength of the magnetic field B.

The secondary (or transmitter) supplies the controlled current to the coils to generate the magnetic field, and amplifies, filters, and converts the resulting signal to user outputs such as 4 – 20 mA, frequency, or digital communication information (HART, FOUNDATION fieldbus, Profibus).

In the modern pulsed DC magmeter, the generated signal is actually quite small: typically on the order of 100 uV per foot per second flow velocity (300 uV per meter per second velocity). Because this signal is so small, magmeter designers and users must take steps to minimize noise and to maximize noise rejection. One of these steps is proper grounding of the system.

Earth / Safety Grounding

To prevent hazards to operating personnel, electrical equipment must always be installed and wired per local electrical code. For AC powered equipment, this usually takes the form of connection of the case of the equipment to Earth ground.

This is usually done through the connection of the earthed green wire to the ground lug provided in the wiring area of the magmeter transmitter. If the transmitter is integrally mounted to the sensor, this automatically connects the sensor to earth ground as well.

It is common that the adjacent piping to the magmeter will provide a connection to Earth ground. A connection to Earth ground is also commonly made at the transmitter through the power connections.

It is important that if both Earth ground connections are established, the impedance between them must be very low. If the impedance between these earth ground connections is high, it can result in a high current through the coil shield wire.

Basic Process Grounding

Establishing a process ground is one of the most important installation details. Proper process grounding ensures that the sensor and fluid are at the same potential so that only the induced flow signal is measured. Why is this necessary? To answer this question, lets look at how the magmeter sensor and the transmitter are connected electrically.

In a typical pulsed DC magmeter, the flow signal is connected to a differential amplifier that is electrically isolated from the case of the transmitter. The process of grounding provides a stable reference for this differential amplifier.

In the majority of applications, the best and most stable reference is earth ground itself. By connecting the magmeter sensor, the fluid, and the reference for the amplifier to a stable, noise free reference point, the user is ensured of getting the best performance from their magnetic flow meter.

Comments

Post a Comment