Some level switches use a float to sense the level of a liquid surface, actuating an electrical switch by the motion of the float. The electrical schematic symbol for a level switch is actually based on this type of mechanism, with a round “ball” float drawn as the actuating element:

An example of this technology is a level switch manufactured by Magnetrol, with two such switches shown in the following photograph of a steam boiler. These switches sense water level in the steam drum of the boiler:

Float level switch

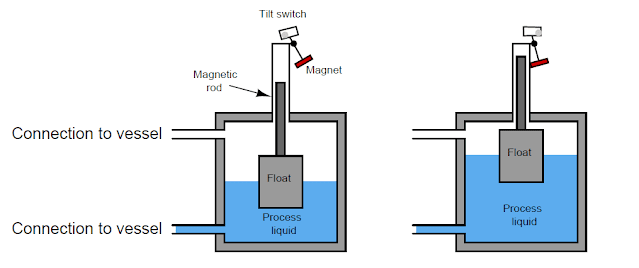

The Magnetrol float switch mechanism uses a mercury tilt bulb, tilted by a magnet’s attraction to a steel rod lifted into position by a float.

The float directly senses liquid level, positioning the steel rod either closer to or farther away from the magnet. If the rod comes close enough to the magnet, the mercury bottle tilts to change the switch’s electrical status:

A feature of this design is complete isolation between the electrical components and the “wet” components sensing the liquid level.

The steel rod moves inside a non-magnetic metal tube, with the tube sealing process fluid pressure from escape while still allowing the magnetic tilt switch to sense float position.

Simpler float switch designs also exist for direct installation in open (vented) process vessels, resembling the float valve assembly on a water-flush toilet.

Any “limit” style switching element will work here, including inductive proximity switches, to sense the float’s position in an environment where no isolation need exist between the switch and the process fluid(s):

The information you have shared here is really informative as it contains some great knowledge which is very helpful for me. Thanks for posting it. Keep it up. Buy Amorphous nanocrystalline magnetic cores

ReplyDelete